One of most common seen molding defects is discoloration. It is a cloudy or hazy discoloration of the plastic on the surface of a finished part, but when you check the mold surface, you won’t see this on it.The defect is not only in color but also gloss visually unappealing, the plastic in that area can be weaker than in the rest of the part. Sometimes, no matter how hard you adjust the molding parameter, the issue is still there. It is more serious on textured plastic surface, some area is is dark cloudy while the rest is gloss. The whole part looks annoying. For some parts that require high image, application of painting to cover the defect maybe a choice, which may increase production cost as well. However, money could not solve all issues. Some products are environmental and require flame retardant, the discoloration becomes a challenge that puzzles a lot of technicians.

This discoloration defect is often found around gate locations, it might be color difference between the area that is around the gate and the area that is far from the gate, or certain area and its neighborhood. Normally, the defect happens more frequently on large parts and textured plastic parts that has high shrinkage rate. The defect area may vary as the parameter changes.

What is the reason behind this?

Firstly.For a same product, different molding parameter will cause color difference. The parts injected at high speed and high pressure is more bright, vice verse. This is very commonly seen.

Secondly,If there is ribs with plastic flowing vertically on the back VS the front, then the front side of the rib is dark or cloudy.

Thirdly, the plastic in that area can be weaker or darker than in the rest of the part.

Though the third defect is the most difficult one, but 3 types are caused by the same reason.

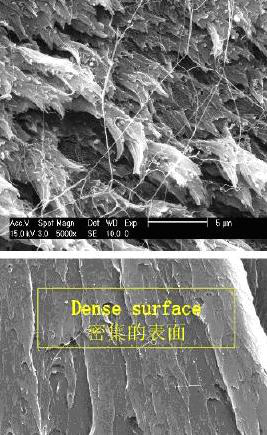

As know, plastic injection mold is a tool to copy molded plastic parts. In other words, melt plastic runs along cavity and copy each shape of the cavity. Theoretically, if the mold cavity is gloss in surface, the product is gloss. On the other hand, if the cavity is textured then the part is textured surface. It is easily understood. Therefore, for a gloss part, when the parameter is proper, including high material and mold temperature, fast shooting speed, high hold pressure, then the part looks quite bright and gloss. Needless to say, the part is perfect copy, in other words, the melt plastic copies the mold gloss fully during the process of cooling down. However, there are some cases when the hot plastic doesn’t behave so obediently. It escapes and fall off the hot steel surface earlier before it cools down to solid state, this is called “blush”. Once leaving, the heat conductivity of the plastic is reduced greatly and the surface of plastic goes through a the process, re-heating up=>bubble=>Shrink=>Roughness, that looks like cloud.

As shown above,under microcosmic image 2 looks better than image 1 which is gloss with eyes. Then one question is asked, when the hot plastic escape earlier from the hot steel? That is when tendency of mold inside pressure to “push” plastic outwards is lower than that of the hot material to shrink inwards. This helps to explain when the discoloration happens more in below cases:

1.Parts that have high shrinkage are liable to get cloudy on the surface.

- When injection Pressure and hold pressure low

In a word, when hot plastic runs, the mold pressure on the cavity is not always balanced, some area has higher pressure while other area has lower pressure. It is impossible that the plastic cloud will show on the high pressure area where the part is gloss, vise verse.

Where there is high pressure and where is low pressure on the part?

1.From the same product, the area that close to get gate usually under high pressure, vise verse.

- For a small product, thin wall area carries high pressure while thick area low pressure. “delayed flow”is exceptional.

- For a product, where there is round on the corner for plastic flows to rib branch, the pressure is low.

For long and large plastic part that has high shrinkage rate, the defect is often found in below areas.

1.Gate location gloss while far area cloudy

- Area of thin plastic is gloss while thick wall cloudy.

- Flat surface gloss while corner cloudy.4.Flat area is gloss while the surface that has rib on the back is cloudy

- Area where plastic runs naturally is gloss, while area of “delayed flow”is cloudy. ,

How to Beat the Blush

Here are some common causes of gate blush in plastic injection molding and how they can be addressed:

- Gate is too small or the wrong style for the material.The gate restricts flow as the part fills. But, if it is too restrictive for the required flow, the material will react and blush will appear. The fix: review the gate size against the nominal wall thickness and material.

- Injection fill speed is too high.The speed at which resin enters the mold has a big impact on finished parts. If the mold is filled too quickly, the molten plastic will react to the flow restriction at the gate. The fix: adjust the fill speed until the optimal rate is achieved to prevent blushing. Careful—slowing the fill speed down too much may introduce other problems.

- Injection pressure is too low.In order for a part to be formed properly, the resin must enter the mold with enough pressure that a consistent speed is achieved. If the pressure limit is set too low, then the flow may hesitate and accelerate. The fix: increase the fill pressure limit.

- Melt temperature is too high or too low.Success in plastic injection molding relies, in large part, on achieving the right flow. Plastic that is either too hot or too cold will not flow properly, which means it won’t fill the mold properly. The fix: find the ideal barrel heat for the material and the mold you are using.

- Nozzle diameter is too small.When the nozzle diameter is too small, it compounds the flow restriction in downstream runners and gates. The fix: enlarge the nozzle diameter. Ideally, the nozzle tip should be the same size as, or slightly smaller than, the sprue bushing opening.

- Gates are not in the right locations.We’ve blogged about gate location in the past. If gates are positioned such that thin areas fill first, the plastic there will begin to harden before thicker areas receive material. The fix: ensure that gates are positioned so that thicker-walled areas are filled first.

The Key to Being Blush-Free? Experience.

The causes and solutions listed above are just some of the factors when it comes to gate blush in plastic injection molding. The takeaway is that for every issue that impacts the quality of a part, there is corrective action you can take. The key is knowing what to do. As a Denver-based leader in our industry for more than two decades, we have a tremendous amount of experience to draw on. If you’ve got questions about your next project, or need help resolving an issue with a current project, we’re happy to help.

Español

Español