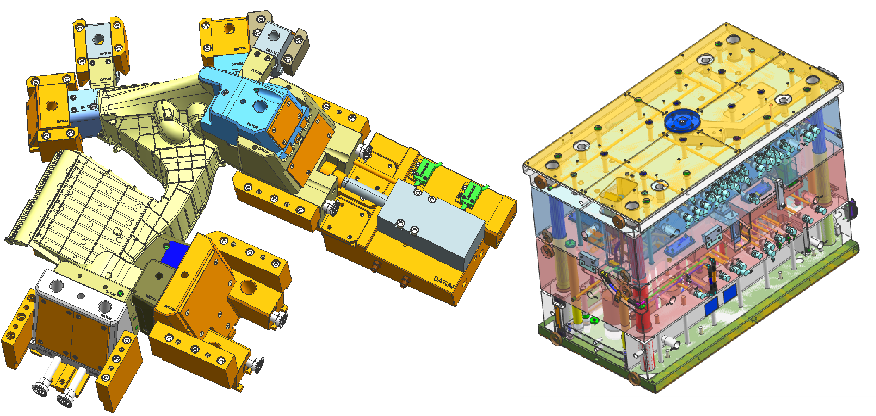

Design for Manufacture and Assembly

Our engineering team are 100% focused on tooling DESIGN FOR MANUFACTURABILITY , FOR FUNCTIONALITY, FOR COST REDUCTION AND SUSTAINABILITY. Do you need design validation for your innovative project?

Get a free DFM

We know that any project may run the risk of failure without the solid foudnation of a good Mold Design. That is why HS Mold invests so much in the design – focusing on design for use, reliability, for functionality, sustability and manufacturability.

HS’s engineering team consists of 15 qualified molding and tooling engnineers with over 10 years of experience in plastic industry. Our engineers cooperate with your mechanical engineers starting from early design stage where design flaws and cost waste can be addressed based on the original design and chosen manufacturing process. Every project will start with a DFM covering Gate Location, draft angles, undercuts, and more in the design stage in order to achieve the quality/cost requirements of customers

At HS,innovative plastic mold design software and technologies are applied to create mold designs based on SPI standards. For every plastic project, we will run moldflow analysis to evaluate all mold designs and parts prior to development. Our design/engineering technologies includeOur design/engineering technologies include:

- Pro/Engineer/UG (3D)

- AutoCad (2D)

- Moldflow analysis (Plastic flow/deform simulation)

- MasterCam (CNC Programming)

Español

Español