Every mold maker knows that proper mold venting is crucial for manufacturing quality plastic injection molded parts. During the injection molding process, the air existing in the mold needs to be released, otherwise the melt will compress and trap that air in the cavity, causing burnings,short shots, bubbles, welding lines or cracks in the molded plastic part.

How do you vent the mold? There are a few nonstandard venting solutions that can be added to cavity venting to improve mold performance as below:

- Open vent groove directly

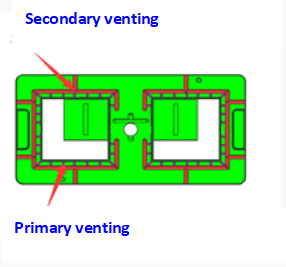

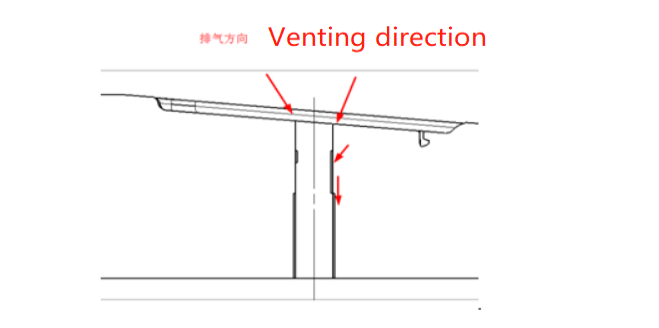

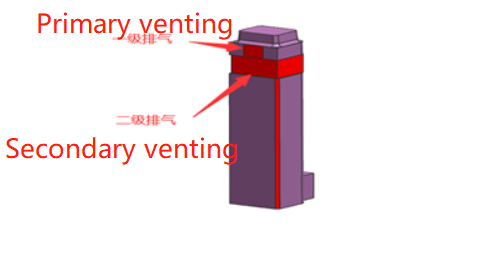

Usually the vent groove, or vent channel are machined on the flat surface in either peripheral or direct way. There are primary and secondary venting channels.

- Use clearance of ejector pins and ejector sleeve.

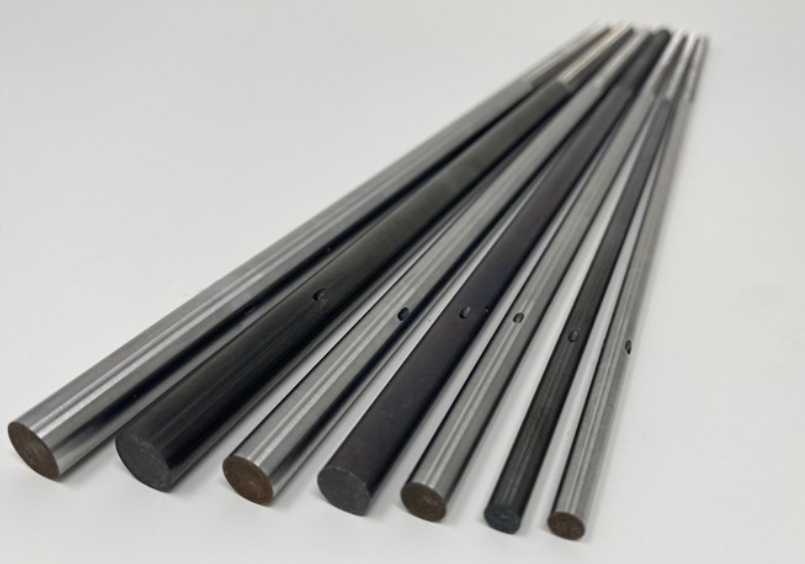

There is clearance of around 0.01-0.02mm between ejector pins & ejector sleeves and core/cavity. This could be used as “natural” vent. In this case, no need to machine extra venting channels. We just need to place the ejector pins on where trapped air maybe present on the plastic parts. For for some high quality plastic molded parts, extra venting holes are machined on the ejector pins as well.

- Use of Vent Pins

We usually use ejector pins to replace vents pins which are featured with with 6 or 8 grooves machined along the body to allow the gas/air to escape. Vent pins are usually located at the center of the air trap to achieve best results.

- Divide mold inserts

During the machining process, the mold cavity can be divided into inserts to increase the number of possible venting areas. When parting lines and sliding elements don’t allow for enough venting, dividing inserts is a good option for plastic product that has trouble of gas trap, but this may increase manufacturing cost.

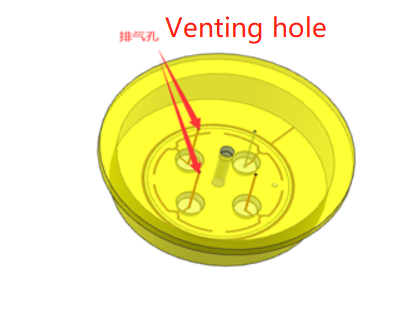

- the Use venting holes

When there is enough room within internal parting line of a plastic part, we usually add an extra venting hole to release the gas on the core on the base of the necessary venting groove.

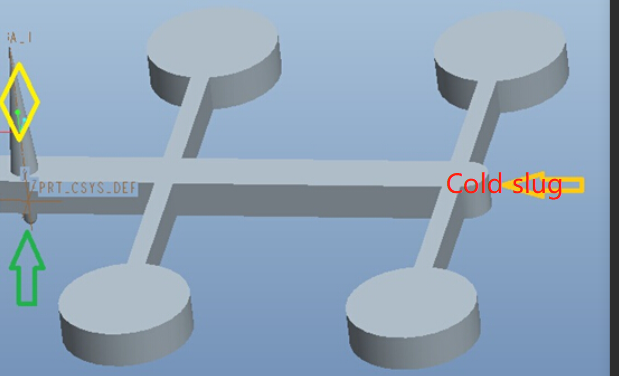

- Use cold slug to vent molds

During the process of injection molding, it is very easy to see problems of air trap at the end of part fill. In this case, we could design a piece of “extra plastic” at the end of the part where two melts join. This helps to exhaust the trapped air into this piece of plastic,thus improving welding line a lot. The disadvantage is that that we have to design extra ejector pins to release the cold slug and have to use labor to cut off the flash after ejection molding. No need to vent at the cold slug. The “slip fit” between the cold-well ejector pin and its bore is more than sufficient .

We are a professional mold maker that designs and builds complete turn key tooling solutions for plastic molding companies in the application of Automotive, Aero, rigid Packaging and other industrial areas. If you have any project that needs engineering support, reach us to learn more.

Español

Español